Metal cutting is one of the key processes in metalworking industries, used for shaping and preparing metal components. This process involves removing portions of metal in order to achieve the desired shape or dimensions Metal cutting is performed using various methods, each suited to specific applications

Metal Cutting Processes Methods and Applications

Category:

Publication Date: 2025/01/17

What You Will Read in This Article

Various Methods of Metal Cutting

- Mechanical cutting

- Mechanical shears: Used for cutting metal sheets, including manual and machine-operated devices.

- Saw cutting: This method uses various saws, such as band saws or disc saws, to cut metals. It is suitable for cutting pieces of different thicknesses.

- Punch cutting: In this method, a metal piece is cut into various shapes using the pressure of a punch and die. Punching is suitable for producing high-precision, repetitive parts.

- Thermal cutting

- Flame cutting (oxy-acetylene): This method uses an oxy-acetylene gas flame to cut metals. It is suitable for cutting thick and large pieces.

- Plasma cutting: This method uses a jet of plasma gas to cut metals. Plasma cutting is suitable for electrically conductive materials such as stainless steel, aluminum, and copper.

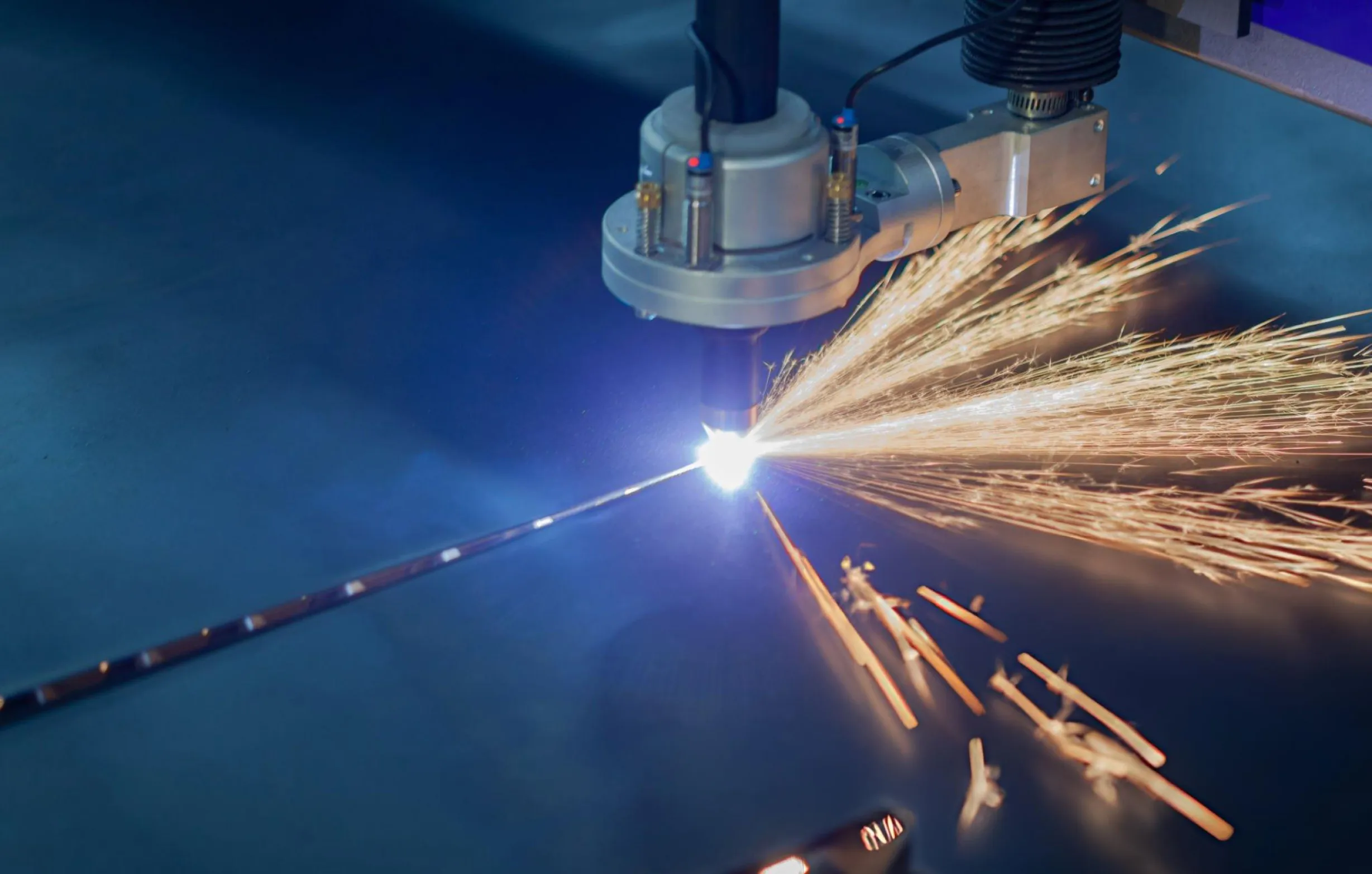

- Laser cutting: This method uses a laser beam to cut metals with high precision. Laser cutting is used for producing parts with complex shapes and smooth cut surfaces.

- Waterjet cutting: In this method, high-pressure water, sometimes mixed with abrasive materials, is used to cut metals. Waterjet cutting is suitable for cutting heat-sensitive materials or materials that cannot be cut with thermal methods.

Advantages of Cutting Processes

- High precision: Methods such as laser cutting and waterjet cutting have very high precision and are suitable for producing parts with precise details.

- Speed: Thermal cutting methods, such as plasma cutting, are fast and suitable for mass production.

- Flexibility: Ability to cut different types of metals with different thicknesses.

Metal cutting applications

- Automotive industries: Production of car body and chassis parts.

- Construction industries: Production of iron beams, metal sheets, and other metal parts needed in buildings.

- Aerospace industries: Cutting precision parts for use in aircraft and satellites.

- Home appliance production: Cutting metal parts for the body and internal parts of home appliances.

conclusion

Metal cutting is one of the basic processes in the production of metal parts, which is carried out using various methods. Choosing the right cutting method depends on the type of metal, its thickness, and the accuracy required. As technology advances, cutting methods are moving towards higher precision and efficiency, which helps improve the quality of final products.

Related Articles